frequently asked questions.

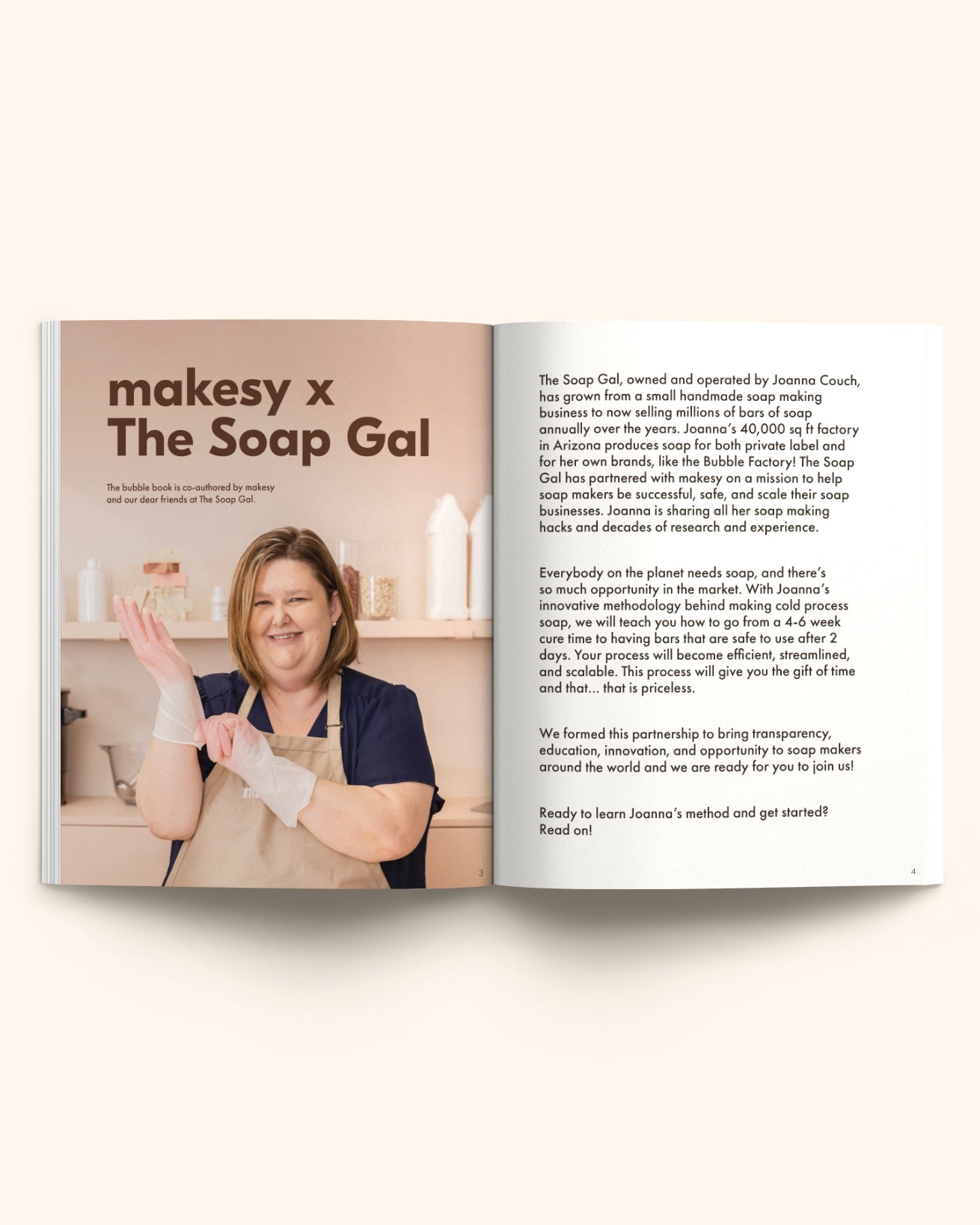

Discover the art of how to make natural soap with our comprehensive selection of supplies from soap molds to soap bases. Whether you're a beginner or an experienced soap maker, we have everything you need to create stunning soaps with ease. From melt and pour soap supplies to proprietory lye cold process soap ingredients, our exclusive soap molds ensure unique results every time. Explore our wholesale and bulk options to stock up on essentials and save. With our premium ingredients and extensive range of soap supplies, you'll be crafting luxurious soaps in no time.

What are the advantages of using wooden soap box molds compared to silicone soap molds for soap making?

When deciding between wooden soap box molds and silicone soap molds, it's important to consider several factors. Wooden molds, such as those crafted from sustainably sourced bamboo, have gained popularity due to their eco-friendliness. They provide excellent insulation, which aids in even cooling and curing of soap. Wooden molds also add a rustic charm to your soap-making process.

On the other hand, silicone molds offer versatility and ease of use. They are flexible and allow for easy release of soap bars. Additionally, silicone molds come in various shapes and sizes, including intricate designs, giving you creative freedom in your soap-making endeavors. For customers seeking a more sustainable option, silicone molds are often reusable, reducing waste in the long run.

The choice between wooden and silicone molds ultimately depends on your personal preferences, the type of soap you wish to create, and your commitment to sustainability. Both options have their unique benefits, making them valuable tools for soap makers.

How do I choose between a crinkle edge and a straight edge soap cutter for shaping and cutting my soap bars?

Selecting the right soap cutter plays a pivotal role in the final appearance of your soap bars. The choice between a crinkle edge and a straight edge soap cutter depends on your desired aesthetic and the style you want to achieve.

Crinkle edge soap cutters are favored for their ability to add decorative flair to soap bars. They create visually appealing wavy or scalloped edges, adding character and uniqueness to each soap slice. This style is well-suited for artisanal and handcrafted soap lines, enhancing their artisanal appeal.

Conversely, straight edge soap cutters offer a clean and modern look to soap bars. They create precise and uniform edges, perfect for soap makers aiming for a sleek and minimalist design. Straight edges are particularly popular in commercial soap production and when consistency is key.

Ultimately, your choice between a crinkle edge and a straight edge soap cutter should align with your soap's branding and the aesthetic you wish to convey. Some soap makers even use both types to cater to a broader customer base.

What are mica powders used for in soap making, and how can I incorporate them to achieve vibrant colors in my soap?

Mica powders are dazzling mineral pigments frequently used in soap making to add vibrant colors and shimmering effects to soap creations. These versatile additives offer soap makers an array of creative possibilities.

To incorporate mica powders into your soap recipes, begin by selecting colors that complement your desired soap design. Mica powders are available in a vast spectrum of shades, including metallics, pastels, and bold hues. Consider the theme or mood you want to convey through your soap's colors.

The process of adding mica powder to your soap is straightforward. Mix the desired amount of mica powder with a small amount of liquid glycerin or a carrier oil like olive oil or sweet almond oil. This creates a mica "slurry" that easily disperses in your soap mixture, preventing clumps and ensuring even color distribution.

When blending mica into your soap, be mindful of the quantity used. A little goes a long way, so start with a small amount and gradually increase until you achieve your desired color intensity. Keep in mind that excessive mica powder can stain the skin or bath surfaces, so it's essential to strike the right balance.

Mica powders are an excellent way to infuse your soap creations with eye-catching colors and shimmering effects. Experimentation and attention to detail will help you master the art of mica-infused soap design.

How can I safely include botanicals and dried herbs in my soap recipes, and which botanicals work best for different soap formulations?

Incorporating botanicals and dried herbs into your soap recipes can add a touch of nature's beauty and enhance the sensory experience of your soap. However, it's essential to follow proper procedures to ensure both safety and the desired aesthetic results.

Begin by selecting botanicals and dried herbs that are safe for skin contact and do not pose any potential irritants. Popular options include lavender buds, rose petals, calendula petals, and chamomile flowers. These botanicals not only enhance the appearance of your soap but also provide potential skin benefits.

To incorporate botanicals, you can either infuse them in your carrier oils or sprinkle them on the soap's surface. For oil infusion, gently heat your carrier oil and add the botanicals, allowing them to steep and infuse their properties into the oil. Strain the infused oil before adding it to your soap recipe.

When sprinkling botanicals on top of soap, consider the visual impact and arrangement. You can create beautiful designs, patterns, or even embed botanicals within soap layers for a striking appearance.

To ensure the longevity of your soap, it's crucial to educate customers on proper storage. Encourage them to use draining caddies to allow excess water to run off and prevent the soap from becoming mushy. Additionally, advise customers to store soap bars in a dry and well-ventilated area to prolong their shelf life.

Overall, botanicals and dried herbs offer soap makers a creative canvas to craft visually appealing and naturally scented soap creations. With proper selection and handling, botanical-infused soaps can become customer favorites.

What are the key differences between melt and pour soap bases and cold-processed soap bases, and which one is suitable for my soap-making project?

Understanding the distinctions between melt and pour (M&P) soap bases and cold-processed (CP) soap bases is fundamental to choosing the right base for your soap-making project. Both types have unique characteristics and applications, catering to different needs and preferences.

Melt and pour soap bases are pre-made, glycerin-based soap formulations that have already undergone saponification and curing processes. They are ready to use and require minimal equipment. M&P bases are excellent for beginners and those seeking a quick and straightforward soap-making experience. They come in various formulations, including clear, white, and organic options, allowing for versatility in soap design.

Cold-processed soap bases, on the other hand, involve the traditional soap-making method that requires the mixing of oils and lye to initiate saponification. This method offers soap makers greater control over ingredients and customization, making it ideal for those who enjoy crafting soap from scratch. CP soap allows for the incorporation of unique additives, essential oils, and botanicals, resulting in fully customized soap bars.

The choice between M&P and CP soap bases depends on your specific goals and preferences. If you're new to soap making or want a convenient and quick solution, M&P bases are the way to go. However, if you're passionate about experimenting with ingredients, scents, and designs, CP soap bases offer more flexibility and creativity.

Ultimately, whether you choose M&P or CP soap bases, both options enable you to craft beautiful and functional soap creations. Your decision should align with your skill level, desired level of customization, and project objectives.

What does "saponification" mean in the context of soap making, and why is it a critical step in the soap-making process?

Saponification is a fundamental chemical reaction that occurs in soap making. It involves the combination of fats and oils with an alkaline substance, such as lye (sodium hydroxide or potassium hydroxide), to form soap. The term "saponification" is derived from the Latin word "sapo," meaning "soap."

This process is critical because it transforms the raw ingredients into soap, where the fatty acids from oils are converted into soap molecules through a chemical reaction. Saponification is responsible for soap's cleansing properties and its ability to lather. Without saponification, soap would not exist.

What is "lye discount" or "superfatting" in soap making, and why is it beneficial for soap recipes?

Lye discount, also referred to as "superfatting," is a deliberate technique in soap making where the soap maker intentionally uses less lye than required for complete saponification. This results in a surplus of free-floating oils in the final soap product.

Superfatting provides several benefits, including increased moisturization in the soap, making it gentler on the skin. It also ensures that there is no excess, unreacted lye in the finished soap, reducing the risk of skin irritation. Soap makers can customize the level of superfatting to achieve specific properties in their soap, such as extra moisturizing or a luxurious feel.

What is the role of glycerin in soap making, and how does it contribute to the soap's properties?

Glycerin is a natural byproduct of the soap-making process and plays a vital role in soap properties. It is a skin moisturizing emollient and a natural humectant, meaning it helps retain moisture. Glycerin is highly valued in soap because it contributes to soap's moisturizing and hydrating qualities, making it gentle on the skin.

Glycerin helps prevent the skin from drying out after using soap, leaving it soft and supple. It is a key ingredient in soap formulations designed for individuals with sensitive or dry skin. Glycerin enhances the overall quality of the soap, making it a popular choice for soap makers and consumers.

What is the International Fragrance Association (IFRA), and why is it important for soap makers to consider IFRA guidelines when using fragrances?

The International Fragrance Association (IFRA) is a global organization that governs the safe usage of fragrances in various consumer products, including soaps. IFRA sets guidelines and safety standards for fragrance usage in personal care items to ensure they are skin-safe.

Soap makers should be aware of IFRA guidelines when selecting and using fragrances in their soap formulations. Complying with these guidelines ensures that fragrances are used at safe and appropriate concentrations, reducing the risk of skin sensitivities or allergies in soap users. More information on IFRA guidelines can be found on the product pages.

Why is it essential to choose the right soap mold, and what are the benefits of silicone molds for soap making?

Selecting an appropriate soap mold is crucial in determining the final shape and size of your soap bars. Silicone molds have gained popularity in soap making due to their versatility and ease of use.

Silicone molds, like those offered by [Your Brand], are made with high-quality "super silicone," known for its flexibility and durability. These molds make it effortless to release soap bars without imperfections, ensuring consistent and professional results in your soap-making projects.